Discrete Manufacturing ERP

Whereas process manufacturers rely on formulas and recipes, discrete manufacturers create products that can be broken down into individual parts. The good news for discrete manufacturers is that they have a wider variety of ERP options than process manufacturers, meaning that the right solution for their business is definitely out there. The bad news, however, is that they are overwhelmed with options. Navigating the immense pool of vendors takes work.

But going into the ERP selection process with some crucial considerations in mind can drastically reduce your search time. Below, we offer some tips to help discrete manufacturers find the ideal ERP software to solve their business problems.

Check Off Discrete Manufacturing Essentials

To promote greater discrete manufacturing performance, some ERP functions are must-haves. As you embark on software selection, seek out the following features:

- Barcode scanning and RFID tracking: Discrete manufacturers require reliable tracking technology to manage individual parts and materials. With data from materials and equipment going directly into your ERP system, you gain real-time insight into quality and performance.

- Product lifecycle management: Unlike process manufacturers, discrete manufacturers usually have a defined life cycle, requiring a PLM module to store documentation and product history. PLM improves accuracy and production control by maintaining a single repository for product data.

- Material requirements planning: MRP is a single tool with the power to cure several sources of discrete manufacturing headaches, including inventory control and lead time calculation. MRP helps businesses maintain low inventory levels by helping them strategically manage types and quantities of materials purchased. Leveraging forecasts and prices, this feature expedites material ordering to fulfill BOMs and promote accuracy and efficiency.

Search by Industry

Just as the same ERP system likely won’t work for discrete and process manufacturing, the same ERP isn’t going to cut it for every industry. Even if you’ve found a solution with the above features, you’ll still need to dig deeper and search for more specific functionality. What if you don’t have the EDI functionality necessary for automotive, aerospace and fastener manufacturing? What if your software lacks built-in support for regulations affecting medical device manufacturers? Begin your search by explicitly seeking out ERP compatible with your industry, validating that the vendors fully support your needs.

Focus on Processes and Pain Points

Once you’ve narrowed it down some, it’s time to check that potential solutions support your manufacturing methodology. If you’re a make-to-order (MTO) or configure-to-order (CTO) manufacturer, you’re likely to need a product configurator and inventory visibility. If you run global locations, multi-currency tools and multi-site management will come in handy. If you adhere to lean manufacturing principles, a lean production module and Kanban workflows are critical assets. Make sure to prioritize the features essential to execute your unique processes.

You also want to focus on your pain points. Chances are, you’re making the move to ERP to smooth over issues that are impacting your company’s bottom line. Before getting deep into your search, you want to start identifying these problems and determining which features are necessary to solve them. Struggling to make on-the-fly changes? Check reviews to see which systems offer the greatest flexibility. Having trouble finding and maintaining data? Research vendor usability and software dashboards to determine if a solution is user-friendly. Prioritizing your processes and needs will lead you quickly to the optimal ERP system.

Why We Recommend Epicor

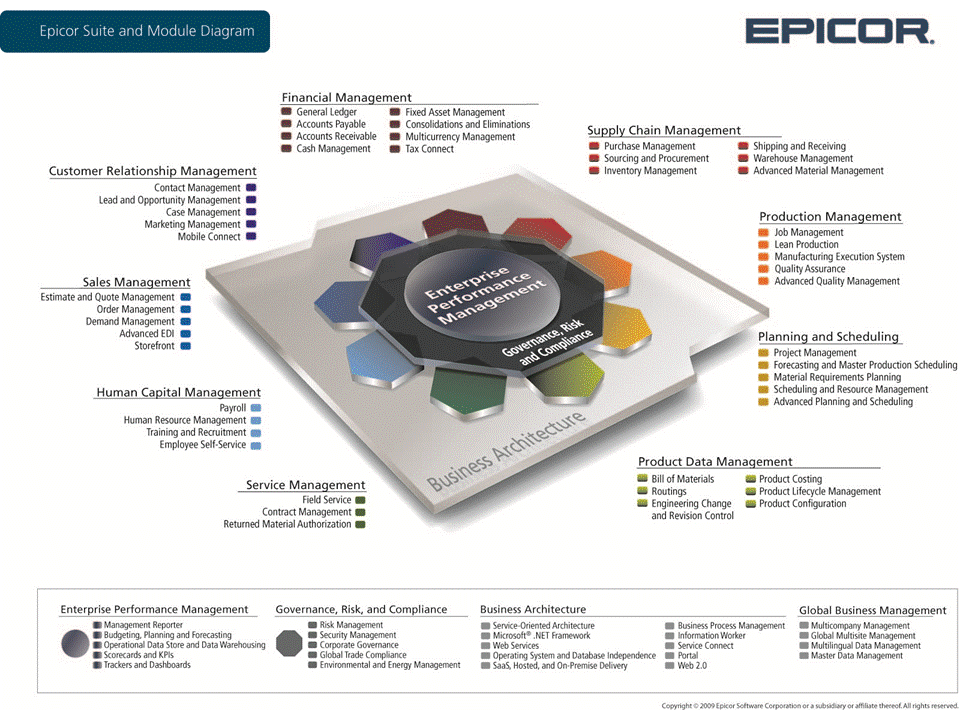

Click on the above image to view the full-size diagram.

In over 20 years as a consulting firm, we’ve found that Epicor ERP checks several boxes for discrete manufacturing, connecting a variety of modules and tools into one solution. With comprehensive functionality, Epicor can tear down departmental silos, promoting instant visibility. The vendor also prioritizes flexibility, making it a solution for enterprises of all sizes across multiple industries. Businesses can quickly configure workflows while individual users personalize their dashboards, making it a user-friendly system that easily supports the nuances of each discrete manufacturer’s processes.

Wrap Up

With endless ERP systems out there geared towards discrete manufacturers, finding just the right one is no easy task. Fortunately, by focusing on specific qualifications, you can quickly narrow down your search.

At Datix, we think Epicor is a good place to start—and end—your search. With support for a wide array of industries and advanced functionality, Epicor can smooth over current pain points and promote long-term growth and improvement.

To reap the full benefits of your ERP, team up with an expert consultant. Datix is a certified Epicor partner specializing in implementations, integrations, customizations, upgrades and more. We know how to align the solution to the unique needs of our discrete manufacturing and distribution clients. Unlike most consultants, we work with you before, during and after the project to ensure you’re getting the most from your software.

Don’t invest in the wrong ERP. Get in touch with Datix today for expert support throughout your implementation!